Chinese and US Semiconductor competition

Can China overcome US sanctions on semiconductors?

Semiconductors play a crucial role in the functioning of computers and electronic devices and are therefore vital ingredients in the functioning of the world's economy. Their production is so important that access to the most advanced chips, produced only by the Taiwan Semiconductor Manufacturing Company (TSMC), is a major factor in the United States's implicit guarantee of the island's independence from the People's Republic of China.

China has spent decades trying to catch up in semiconductor capabilities relative to Taiwan, Japan, South Korea, and the US. Concerned about the consequences of Chinese companies catching up too fast, the US has implemented sanctions designed to slow down this progress. So far, results have been mixed, with Huawei showcasing chips in 2023 that are supposedly only two generations behind those made by TSMC. While this seems not too bad from the Chinese point of view, those only two-generations-behind chips likely involved Western-made equipment from which Chinese companies have now been cut off.

China is a huge consumer of semiconductors, as well as a producer. Unwilling to face potential disruptions to its future supply, it plans to de-Americanize its supply chain and build up its own capabilities for manufacturing the most advanced chips. The future of China’s semiconductor industry, AI development, and a potential military conflict between the US and China are all dependent on whether China will be able to overcome the effects of Western sanctions and successfully develop the most essential kinds of equipment for semiconductor fabrication: lithography, deposition, etching, and process control.

On the other hand, while the United States leads in semiconductor designs, it has lost the ability to manufacture any significant amounts of chips, advanced or not. Can the US regain the capability to manufacture these crucial components of both modern economies and militaries?

How do you make a semiconductor?

A semiconductor starts with highly purified silicon. This is refined into wafers, very thin and perfectly flat cuboids of silicon which are then cleaned and polished. They are then coated with protective oxide and photo-resistant materials before being subjected to photolithography. Photolithography is a process that uses light to transfer a pattern from a photomask to a photosensitive material. The most advanced form of photolithography is extreme ultraviolet light (EUV).

After photolithography, the photo-resistant coating is removed, as is some of the oxide. This process occurs at the nanometer level – a sheet of paper is about 100,000 nanometers thick. Then, the semiconductor is doped, which intentionally introduces impurities to change how the silicon conducts electricity and creates components necessary for integrated circuits, such as resistors, capacitors, and transistors. Following this, ions are implanted for the same reasons as doping before the wafer is heated to repair potential damage from the process so far. Often, the photolithographic, doping, and ion stages are repeated to create even more complex chips. Unsurprisingly, many wafers have defects. Wafer yields - how many chips are created without defects - improve over time as the manufacturers refine their processes. For some chips, TSMC has a yield of 80%, while other firms' yields on the same-sized chips can be only 50%.

Manufacturers and the media conventionally discuss performance in terms of nanometers (nm), representing the distance between transistors on the chip. However, since the 1990s, the nm measurement is better understood as marketing rather than a strict standard. Three-nanometer chips do not have a two-nanometer smaller distance between transistors on the chips than 5-nm chips. Adding to the confusion and akin to how fashion companies use different sizes, similarly marketed chips do not have the same performance metrics. A 10nm chip produced by Samsung can have 50% fewer transistors than an Intel 10nm chip.

The more transistors that can fit on a chip, the faster and more energy-efficient it becomes, thanks to the ability to perform more operations in parallel, reduce signal travel distances and achieve faster processing with lower energy consumption. Squeezing more transistors onto a chip more efficiently is incredibly complicated and capital-intensive. TSMC's capex spending, at $32 billion, is nearly 33% more than the Taiwanese military’s annual budget. ASML, a Dutch company that makes photolithography machines, spent $10 billion and more than 13 years researching and building the most advanced EUV machine to produce chips smaller than 7nm.

Different types of semiconductors perform different roles. The key types are logic chips, which interpret and perform instructions; memory chips, which store information; and analog chips, which convert real-world data into digital data. Central processing and graphics processing units are the most recognizable logic chips due to their inclusion in the laptops and desktops that normal people interact with at home. However, field-programmable gate arrays and application-specific integrated circuits are key sources of revenue for chip manufacturers. Very specific and narrow functions, such as image processing, cryptographic operations, signal processing, and neural network inference, can be addressed by application-specific integrated circuits, handling the workload in a parallel manner and reducing training time and costs for AI systems.

China's leading semiconductor fabricator is Semiconductor Manufacturing International Corporation (SMIC). Given the intensive returns to specialization and the large amounts of R&D, if anyone can compete against the leaders in chip fabrication, SMIC would be the foremost candidate. Founded in 2000 and headquartered in Shanghai, it has 18,000 employees and multiple plants in China. Since 2017, it has been run by Liang Mong Song, a 72 yr old former senior TSMC and Samsung employee born in Taiwan. Song was a key member of the TSMC R&D team that developed 130mn chips in the early 2000s and has over 500 patents to his name. After Morris Chang, the founder of TSMC, first retired in 2005, Song was passed over as the head of R&D at the company and was put in charge of developing more efficient trailing edge chips. Furious at not being allowed to work on leading-edge chips, he left in 2009 to teach at National Tsing Hua University in Hsinchu, Taiwan, as he was forbidden from working at other semiconductor companies for two years due to a non-compete clause.

After 18 months, he moved to South Korea to teach at a university closely associated with Samsung before joining the South Korean giant in 2011 as Vice President and Technical Director. When he arrived, Samsung was trying to develop 20nm chips, two generations behind TSMC. Instead of developing generation by generation, he instead decided to attempt to leapfrog to 14nm, a massive gamble. Fortunately for Song and Samsung, this paid off, and in 2015, Samsung released a more advanced 14nm chip than TSMC’s 16nm. The shocking technological leap led to a massive lawsuit in Taiwan between the two companies, with TSMC arguing Song had broken his non-compete cause. Samsung lost the case, and Song had to step back from Samsung.

In 2017, the head of SMIC, former deputy head of the Chinese Ministry of Electronics Zhou Zixue, lured Song to the company with guarantees he could select his own team and generous financial incentives, hoping Song could replicate what he had achieved at Samsung and catapult his new employer to the front of the pack in chip fabrication. This move was supported by the Chinese state through the Big Fund, a state-backed investment fund that directed billions of dollars toward Chinese manufacturers such as SMIC. Unfortunately for Zixue and Song, the relationship between the US and China deteriorated after Song joined, making the prospect of replicating his success at Samsung much more difficult. Although talent is vitally important in making breakthroughs in chip manufacturing – something they can get in spades – even world-class individuals cannot compensate for the lack of the equipment needed to make the most advanced chips.

ASML’s EUV Photolithography machine costs over $150 million.

Sanctions

China is now subject to sanctions on semiconductor manufacturing equipment and some advanced chips. The first tranche of sanctions was introduced in 2022 by the Biden administration, aiming to prevent American companies from selling advanced chips and some manufacturing capabilities to Chinese forms. After a number of loopholes in those sanctions were pointed out (and exploited), the Biden administration introduced further sanctions in 2023 to iron them out. Before sanctions were tightened, companies could sell chips that weren’t breaching bandwidth regulations but had similar or better performance than explicitly banned chips. Sanctions also went further in collaboration with allies, preventing companies that rely on American patents from selling tools and services to Chinese companies.

Under the latest rules, ASML is forbidden from selling its advanced EUV machines (Twinscan NXE:3600D/C) and its less advanced deep ultraviolet light (DUV) Twinscan NXT1930Di machine to China. The lasers in their EUV machines are nearly ten times smaller than those in DUV machines. A DUV machine can be used to produce smaller chips, albeit in less efficient methods, at the cost of multiple exposures. These methods are not commercially viable for the most advanced chips due to repeated processing and resulting low yields, but DUV machines can still create trailing edge chips and semiconductors for military use.

China is unlikely to escape sanctions on semiconductor manufacturing equipment, as the US, possessing one of the most far-reaching and serious sanctions regimes globally, has effectively persuaded the Dutch, Japanese, and Taiwanese governments to limit Chinese access to both chips and the necessary manufacturing equipment.

If China is serious about building its own semiconductor supply chain, it will have to rely on domestic companies to develop it. At the forefront of the many incredibly complex supply chain challenges Chinese companies will need to overcome is photolithography equipment. Arguably, ASML’s EUV machine is not one but three separate technological challenges - light source/laser, optics, and the instrument worktable - all of which combine to create a machine with over 450,000 components. In etching a semiconductor, a laser in a photolithography machine does not just have to be capable of firing an accurate beam. To create a 13.5nm chip, the laser must hit its target (30 millionths of a meter in diameter) at 50,000 times a second while the target is traveling over 200mph. The many lenses used in the machines must be smooth on the atomic level. Zeiss, the leading (and only) German optical manufacturer capable of providing lenses and mirrors to ASML, likens the challenge of creating mirrors for ASML to “enlarging the mirror to the size of Germany, with elevations no greater than 0.1 mm”. The last major component of an EUV machine is the precision instrument worktable, which in an ASML machine takes over 55,000 components to control the transistors' carving into the silicon accurately.

Shanghai Micro Electronics Equipment (SMEE) is the most advanced Chinese photolithography company, founded in 2002. It’s advanced for China but not for Taiwan or South Korea: its current SSA600 series machines can be used to create 90nm, 110nm, and 280nm chips, generations behind ASML technology. SMEE previously announced plans to release a machine capable of manufacturing 28nm chips, with the initial release scheduled for 2021. As of January 2024, it has still not released a device, although the company was added to the US Department of Commerce's Bureau of Industry and Security trade restriction list (the Entity List) in late 2022, suggesting they may be close.

Contrary to the Chinese government's goals of establishing an indigenous semiconductor manufacturing industry, SMEE's suppliers depend on foreign parts, with Chinese companies UP Optotech, Focuslight Technologies, and MLOptic Corp sourcing equipment from abroad. In 2022, UP Optotech revealed that German company iC-Haus was their second-biggest supplier. Doubtlessly, there will be dozens of other examples demonstrating the very high barriers to an entirely de-Westernized semiconductor supply chain.

Sanctions don’t just apply to manufacturing equipment. The business model TSMC pioneered was fabricating other companies' designs rather than producing chips for a general chip market. By focusing on fabrication methods, they did not have to spend valuable R&D on designing more complicated chips, which is now dominated by US companies. The most successful fabless Chinese semiconductor company, HiSilicon, was acquired by the technology giant Huawei in 2004. Before sanctions, most of its chip designs for Huawei were based on British semiconductor designer ARM and depended on TSMC for manufacturing. In August 2023, they announced the Kirin 9000S, a 7nm chip for Huawei’s Mate 60 Pro smartphones, which were claimed to be manufactured by SMIC. However, it is not actually clear if the 7nm chip is simply leftover rebranded 5nm TSMC stock from 2020, modified stockpiled chips, or an SMIC-produced 14nm chip heavily modified to improve performance.

Fundamentally, the challenge of creating an entirely domestic semiconductor supply chain is vast. It is easily less of a challenge to put a man on the moon. China must simultaneously break through hundreds of different barriers while the most advanced chip-related companies, TSMC, Nvidia, Intel, and Samsung, can continue innovating at the frontier with no sanctions. Attaining its own semiconductor industry or leapfrogging TSMC or ASML to become the leader in fabrication or photolithography are both extremely unlikely.

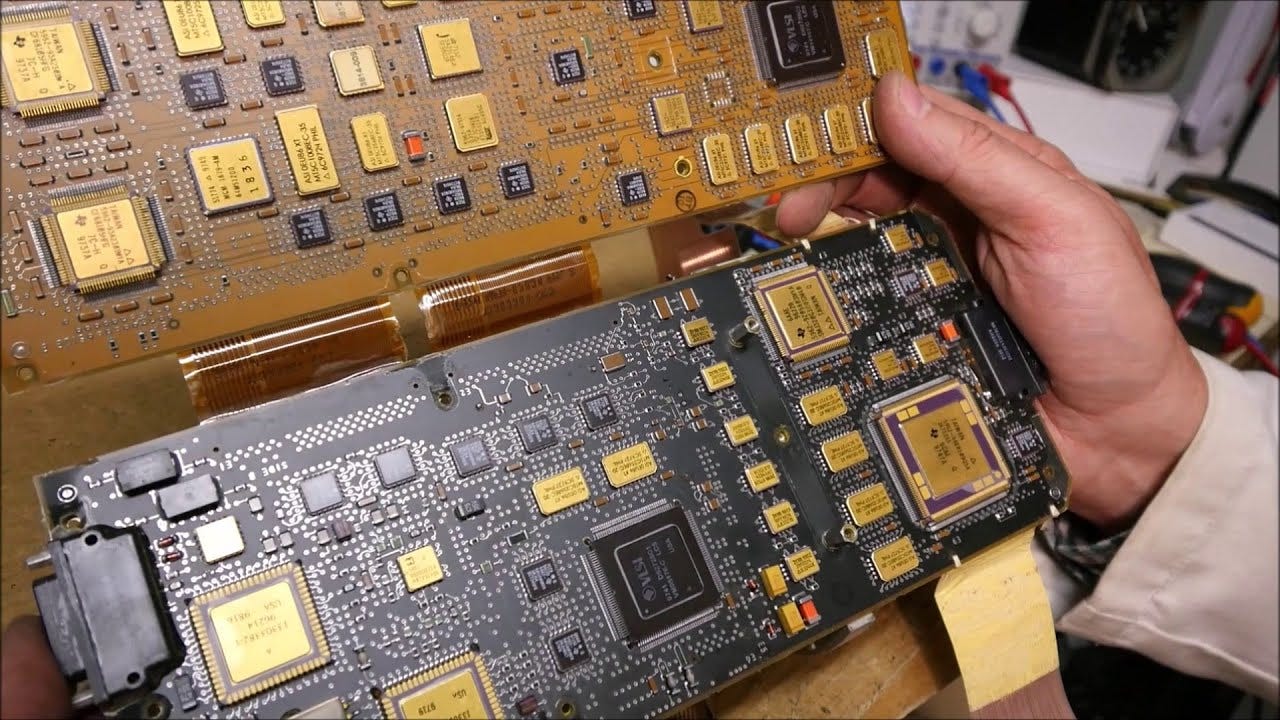

The guidance computer of an obsolete FGM-148 Javelin Missile.

Behind the cutting-edge

Competition at the cutting edge is not the only issue. Most devices that require computing power, like medical equipment, modern cars, and even fridges, use trailing edge chips. The average electric vehicle contains over $1000 worth of semiconductors, and the largest electric car company in the world, BYD, sources most of its chips from within China. The use of these kinds of chips is only expected to rise as they become more and more incorporated into everyday items. The largest Chinese fabs - SMIC and HuaHong Group, rely on global supply chains for parts and supplies, but they are located within China and have some protection from global supply shocks. US fabless chip designers are almost entirely dependent on foreign fabs to produce trailing edge designs, with 80% of their designs being produced in China and Taiwan. Over the next three to five years, China is anticipated to increase trailing-edge (50-130nm) capacity equivalent to the combined capacity added by the rest of the world. This expansion will bolster a robust supply chain for goods China produces for Western economies, which they currently depend on. While autarky in semiconductors is a Chinese aspiration, the US recognizes this is not a realistic goal for a free market liberal democracy. To keep the global supply of semiconductors flowing, it must work to ensure peace in East Asia - a goal made more difficult by an overstretched US Navy and long lead times to replace precision munitions that require semiconductors.

While chips for US military use are sourced from a Department of Defense program called the Trusted Foundry, only 2% of the chips required by the US military are sourced from US-based foundries. F35 fighter jets, the most advanced fighters on the planet, rely on chips made by TSMC. The small scale of current production contributes to shortages in a wide range of military equipment.

As a market economy, the US is also at the mercy of what US-based foundries decide to manufacture. The US was left without 7nm production from 2017-22 as Global Foundries acquired a trusted foundry from IBM and decided to produce less advanced but more profitable chips. The overwhelming majority of military equipment uses trailing edge chips because progress is so fast in chip design, and military equipment needs to be tested to ensure it is resilient. A Javelin missile requires over 200 semiconductors, none of which will be cutting edge. The US has recognized this deficiency in domestic production, passing the CHIPs Act in 2022, allocating billions of dollars in support for domestic manufacturing.

It is only natural when a government decides to spend tens of billions of dollars of taxpayers' money on domestic production of something, the government will end up heavily depending on a domestic company. Although the CHIPS Act has spurred TSMC to invest in a foundry in Arizona, this plant producing 4nm chips won’t open until 2025, and a second plant won’t open until 2027 or 2028, with no guarantee from the company it will be producing cutting edge chips. It seems the major beneficiary of CHIPS subsidies will be Intel. Unfortunately for the US government, Intel is no longer a leader in chip manufacturing after a disastrous decision in the early 2010s to ignore EUV in manufacturing next-generation semiconductors, which led it to lose significant market share to TSMC and Samsung. Intel faces higher labor and capital costs from manufacturing in the US, which Asian-based manufacturers don’t have to worry about. The CHIPS act talks a big talk about reshoring advanced semiconductor manufacturing to the US, but Intel will face significant challenges in attempting to regain the lead it lost, even with US government subsidies. Just as China’s Big Fund found out, throwing money at the problem does not guarantee success. However, although the CHIPS act will likely not see US companies returning to leadership in semiconductor manufacturing, it will guarantee some domestic manufacturing capability and start to increase US supply chain robustness.

Conclusion

Perhaps only China or the US could tackle the immense technical challenge of developing a domestic semiconductor manufacturing equipment industry. As it stands, China's attempt to domesticate semiconductor manufacturing is likely to be unsuccessful, and any claimed domestication will probably depend on foreign components. It also seems implausible for China to successfully catch up to leading semiconductor fabricators in the scale or performance of chips, although it can produce chips for specific purposes.

The United States' challenge is that its embracement of market forces has driven semiconductor manufacturing away from its own borders, while the importance of chips to the world economy has only increased. Although it is attempting to increase its own domestic production through the CHIPS Act, leadership in semiconductor manufacturing is likely to remain in Asia.

SMIC/Huawei have already passed Intel at the 7nm level and are expected to ship 5nm this year.

China is the only country with indigenous, end-to-end chip manufacturing, and builds as many fabs each year as the rest of the world combined.

Just sayin'.